JBS Fabrication Ltd is our leading engineering solutions & fabrication division specialising in the structural & pipework fabrication in a range of ferrous and non-ferrous materials to UK & Worldwide Codes & Standards.

Our independent machining, piping and structural steel fabrication workshops accommodate an extensive range of materials and processes.

The breadth and depth of completed contracts has elevated JBS to an industry leader for repair order, minor modification, metal fabrication services, and finite element analysis (FEA).

We use the best available technology, a dynamic, flexible approach, and our wealth of experience in both structural fabrication and design engineering, to ensure a strong track record backed by a flexible competitive commercial model.

Sectors

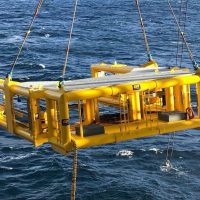

JBS Fabrication Ltd provide qualified welding, fabrication installation & commissioning engineers globally with experience on jack-ups, FPSOs, Platforms, various drilling rigs and onshore facilities. We have grown from working in the North Sea to doing jobs all over the world.

JBS carries out OEM equipment installation along with repairs and modifications for the Energy, Space, Defence and Renewable industries, often mobilising personnel and equipment at short notice.

With the backing of our onshore engineering and fabrication services, the division can provide impeccably integrated jobs from design to delivery to meet the project’s needs.

Our fabrication & engineering services include:

- Structured Steel Fabrication

- Electrical Engineering Mechanical Design

- Offshore Welding, Fabrication & Repair

- Finite Element Analysis (FEA)

- Stainless Steel Fabrication

- SuperDuplex Piping

- Carbon Steel Piping Fabrication & Modification

- Compex Electrical, Hydraulic & Instrumentation Installation

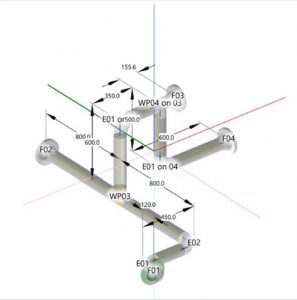

JBS utilise the automet® industry leading pipe measurement system to ensure our clients have the best available technology for pipework. The system has been used in the onshore & offshore energy sector / pipe fabrication & servicing industries for over two decades.

automet® is a comprehensive pipework design measurement and reporting system for fabrication, installation, and survey of pipework systems. Traditional pipe measurement techniques are slow and often result in poor design integrity – leading to costly manufacturing errors, on-site re-work and client disputes. automet® is a revolutionary 3D digital pipe-spool measurement system that dramatically simplifies the measurement process – delivering unmatched integrity at a fraction of the time and cost of traditional systems.

JBS imports the spool design CAD files or enters the design data manually. automet® will instantly render a precise 3D digital model of each spool. Next, measure the spool using a Leica Total Station survey instrument coupled with our proprietary position capture tools. automet® will automatically generate a comprehensive set of QA reports detailing any manufacturing deviation from the original design. automet®’s powerful data capture and QA capabilities enable reliable and easily verifiable manufacturing accuracy within design tolerances.

Contact JBS Fabrication Ltd for all your pipework requirements – www.jbsgroupglobal.com