JBS Fabrication Ltd has partnered with Breton Industries USA to provide blast, frag, fire, ballistic and arc flash protection to safeguard people against hazards using our BlastTac range of products.

BlastTac utilises the best available next-generation fabrics to create the world’s safest technologies and innovations. High pressure test containment solutions inherently utilised steel barriers. Blastac solutions are lighter, more flexible, they are also verified by third parties such DNV GL. BlastTac is the best available technology and next generation for pressure test blast containment.

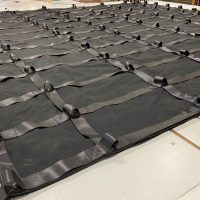

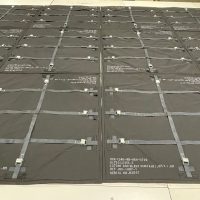

BlastTac blast curtains and blast blankets are incredibly lightweight, completely non-flammable (when combined with FireMax fire protection) and more effective than steel.

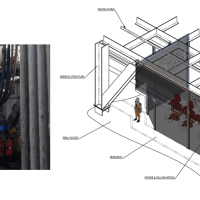

A complete turnkey solution is provided by JBS Group to include defining the reaction forces required to withstand the impact forces, then building a complete structure. The structure will comprise the blast curtains/blankets or wraps with all of the attachment points and fixings such that the system can be installed by the JBS Peterhead installation team at client locations all over the world.

For protection in high-temperature applications, BlastTac created FireMax®. FireMax curtains, blankets, and fire barriers provide fire, heat and arc flash protection in addition to blast protection. Truly non-flammable, these curtains and blankets will not burn, melt or ignite and will also shed molten metal, certain chemicals, flammable liquids, and other molten substances. FireMax fire protection items are also re-usable even after intense heat and flame exposure.

The key to safety is in your hands – JBS BlastTac advanced fabric solutions are internationally recognised and utilised in many industries providing cost effective blast protection for personnel and equipment.

Solutions Offered:

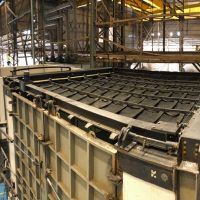

- Automated Pressure Test Bay Roof Protection

- Blast Wave and Frag Containment

- Fire Protection using Firemax – Designed to survive fire and heat. FireMax is truly non-flammable

- Explosive blast and impact protection from both sides

- Acoustic Protection and Noise Reduction

- Arc Flash & Pressure Test Barriers, Blankets, Wraps & Curtains

- Ballistic Protection

- Blast Walls, Windows for Buildings and Parking Lots with Flexible Installation Plans

- Designed to contain flying debris and explosive overpressure – our blast protection systems offer exceptional protection and blast containment in the event of equipment failure during pressure testing

- Complete turnkey solution from design, site survey, manufacture and installation onshore / offshore global locations

- 3rd party verification, assessment and certifications from DNV, BV and ASTM

Ballistic, Arc Flash, Explosive Blast Protection and Frag Protection:

JBS blast curtains provide impact and blast protection from both sides of the barrier. JBS qualify all product performance data either by a physical test validation/qualification which can be witnessed by the client, Finite Element Analysis (FEA) using static and dynamic modelling or a standard type UL 752 industry test. The purpose of the test is to validate the product’s ability to stop and reduce velocities of blast fragmentation while significantly reducing peak pressures.

Our ballistic and blast products are manufactured from innovative patented “best available technology” materials that have undergone rigorous testing and detailed scientific analysis. Thin curtains, light weight and complete flexibility ensures the product is a world leader. JBS provide a complete turnkey global service from design, installation and commissioning to ensure a long term durable, cost effective solution.

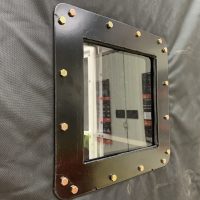

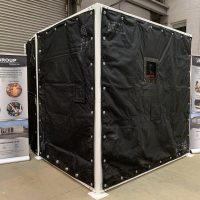

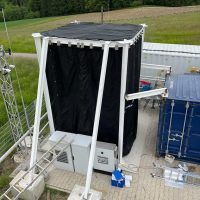

JBS portable pressure test bay (PPTB) with ballistic glass viewing panel, suitable for:

- Pressure testing at different locations

- Ready-to-go high pressure testing solution in your workshop

- Ease of assembly, disassembly and storage

Arc Flash Protection Curtains Installed in Switchgear Room at 1040MW Peaking Power Generation Facility in New York USA

JBS portable pressure test bay with ballistic glass viewing panel allows clients to test equipment in a flexible and safe environment. Due to the flexible design of the PPTB, we can easily incorporate your specific dimensions, logistics, handling and testing requirements. From open top, opening front and back doors, multiple viewing panels, inside lights, etc.

JBS PPTB provides a turnkey pressure test solution designed around the equipment to be tested.

JBS ballistic protection products are issued with a V50 testing sheet. The most common standards for testing the fragmentation resistance of a ballistic product are: US Standard – Mill STD 662 E, UK Standard – UK / SC / 5449, NATO Standard – STANAG 2920. Products are NIJ 0101.06 compliant.

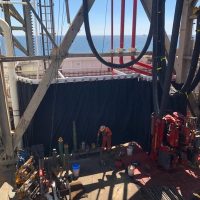

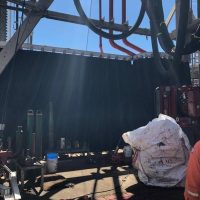

Offshore oil & gas installation blast protection

Every two to three weeks, all offshore rigs are required to perform BOP/ C & K Manifold pressure tests. As a result, high-pressure testing requires rig floor operations to shut down which is costly for rig contractors and operators. (Reference API standard 53 – Blowout prevention for Drilling Wells).

Introducing, the next generation best available technology for oil & gas installation blast containment – the SB72FM Series. These blast curtains and blast blankets are engineered specifically for blast protection on gas and oil rigs. With up to hundreds of hours lost to testing every year, the SB72FM Series is designed to reduce the time that rig operations are shut down.

BlastTac is the only truly non-flammable fabric available which has been approved by the oil & gas industry for hazardous area installation at onshore and offshore locations. Our solutions provide fire and blast protection, acoustic protection, and perform as an arc flash barrier making them truly versatile.

High pressure testing blast protection

The SB72FM Series is effective against both deformable and non-deformable threats, which are more prevalent and lethal than bullets. Similarly, SB Series blast curtains and blast blankets are UL752 tested to levels 1, 2, 2+, 3 and 3+. Because the SB Series is able to survive ballistics, frag, fire, and give arc flash protection, it is also employed by USA military and police forces for protection against gunfire and explosions.

BlastTac blast curtains and blast blankets are lightweight, durable that also provide long-lasting waterproof protection. The SB72FM Series is equipped to provide reliable ballistic protection against high-pressure projectiles, blasts and fragments.

Firemax® fireproof protection

For high-temperature and fire protection, the SB72FM Series features new FireMax 777 technology. This woven fabric is designed to survive fire, heat and arc flash using a single blast curtain. Because it is truly non-flammable, FireMax material will not burn, melt or ignite and will also shed molten metal, certain chemicals, flammable liquids and other molten substances making it the perfect fire barrier. Similarly, it is breathable, water-resistant and durable in harsh weather conditions.

Certification

Independently tested and certified by Chesapeake Testing Labs, located in North Carolina, BlastTac blast curtains and blast blankets are tested in accordance with U.S. Military, UL standards and ASTM International Test Standards. An independent assessment was also performed by DNV GL to confirm that the SB Series is equipped to provide oil rig blast containment.

3rd party verification, assessment and certification by ExxonMobil, through their engineering partner Aker Solutions, completed the Lloyds certification process for the entire JBS pressure test blast curtain solution.

Sectors

- Defence

- Oil & Gas Onshore & Offshore

- Space

- Mining and Smelters

- Industrial pressure test centres

- Employed by USA military and police forces for protection against gunfire and explosions

- Power Generation